High Quality Defoamer Desiccant Masterbatch

Better water absorption, powerful water absorbing could up to its weight 20%

Perfect diffusing,less effect on products glossing and coloring.

Good corrosion resistance

Non-toxic and environment-friendly, no hurt on worker

Product Description

Desiccant masterbatch is an innovative drying agent, also known as defoaming masterbatch or water absorber, used to eliminate moisture in virgin and recycled LDPE, LLDPE, HM, PP, ABS, PA, PV, and PVC. It is primarily applied in injection molding, film production, and sheet manufacturing. This masterbatch acts as a plastic dehumidifier for recycled PP and PE materials. It is a newly developed functional masterbatch designed to address moisture issues during the processing of recycled PE and PP. Desiccant masterbatch can be added and easily mixed with recycled materials prior to plastic molding, allowing for processing without the need for drying. This user-friendly solution improves production efficiency and reduces energy consumption.

The production process can be carried out by mixing this masterbatch with damp plastic materials, with recommended amounts of 1.0% to 2.0% for blow molding and 2% to 5% for sheet and injection molding. Customers should adjust the amount based on the level of moisture in the plastic.

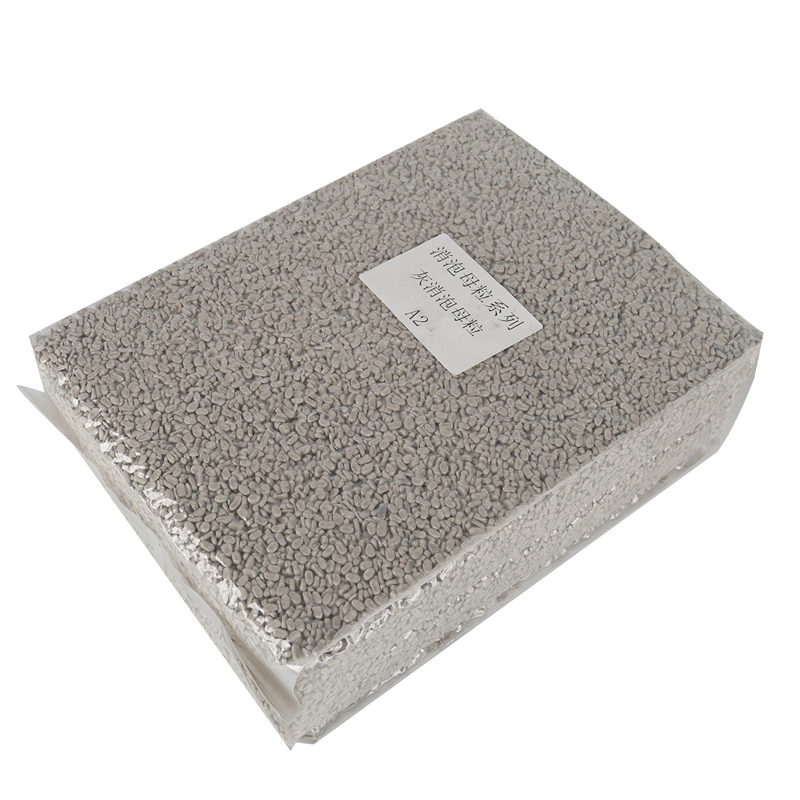

| Appearance | Solid particle |

| Color | White, Grey, Black |

| Density (g/cm3) | 1.5+/-0.1 |

| Melting Point | 190 +/- 10℃ |

| Plasticity/softening | Very well |

| MFR(melt flow rate) | 5kg, 190℃, 5-12g/10mins, 10g/10mins |

| Water Absorption/Moisture absorption rate | 50%-100% |

| Package | Vacuum package, 5 KG of each |

Application

Blown film & lamination

PP non-woven fabric

Blow molding

Injection molding

Thermoformed sheet

HDPE/PP pipe extrusion