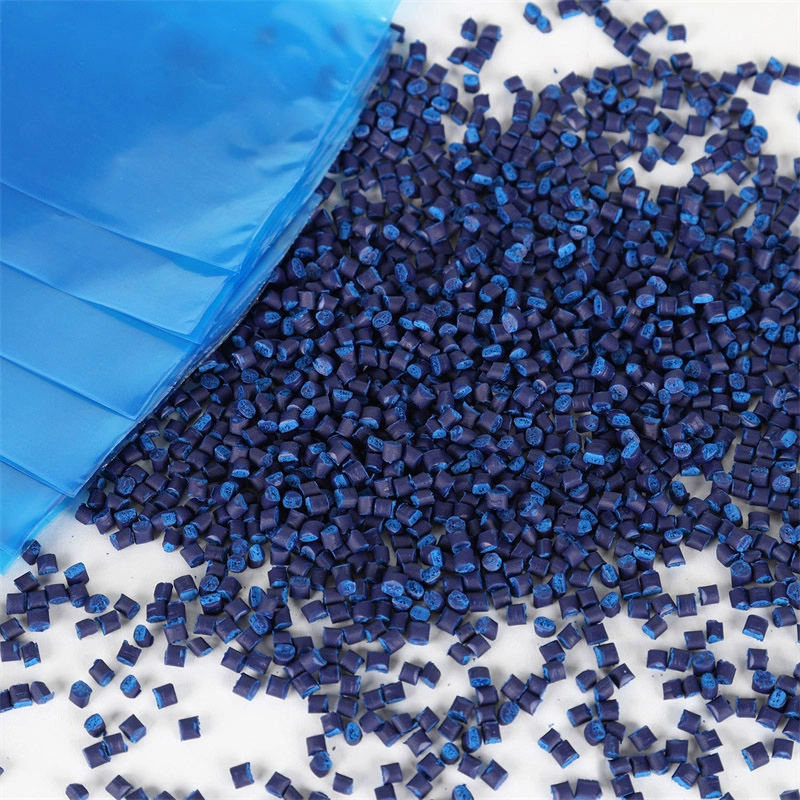

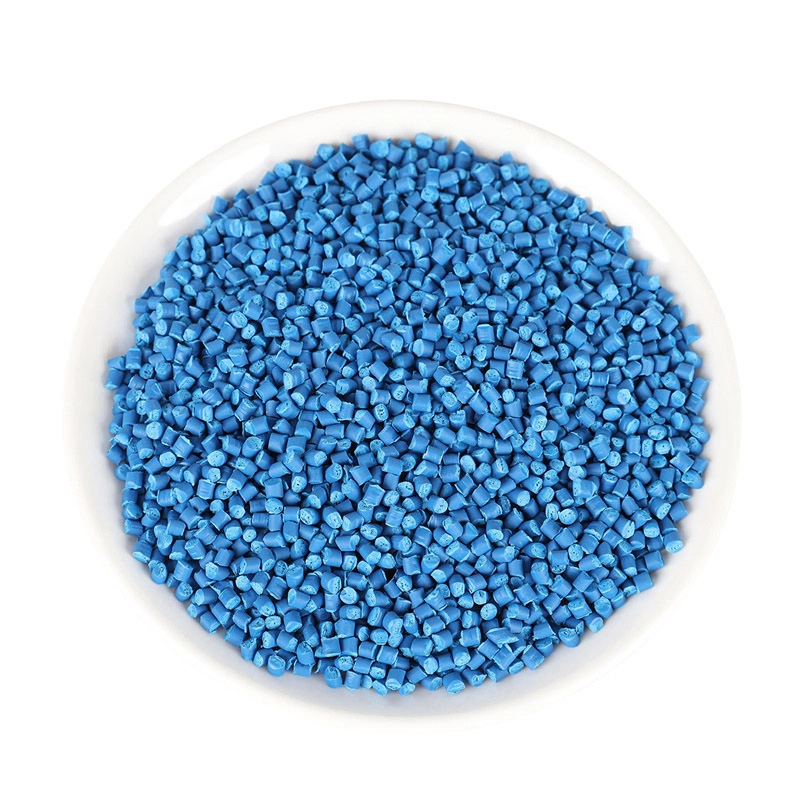

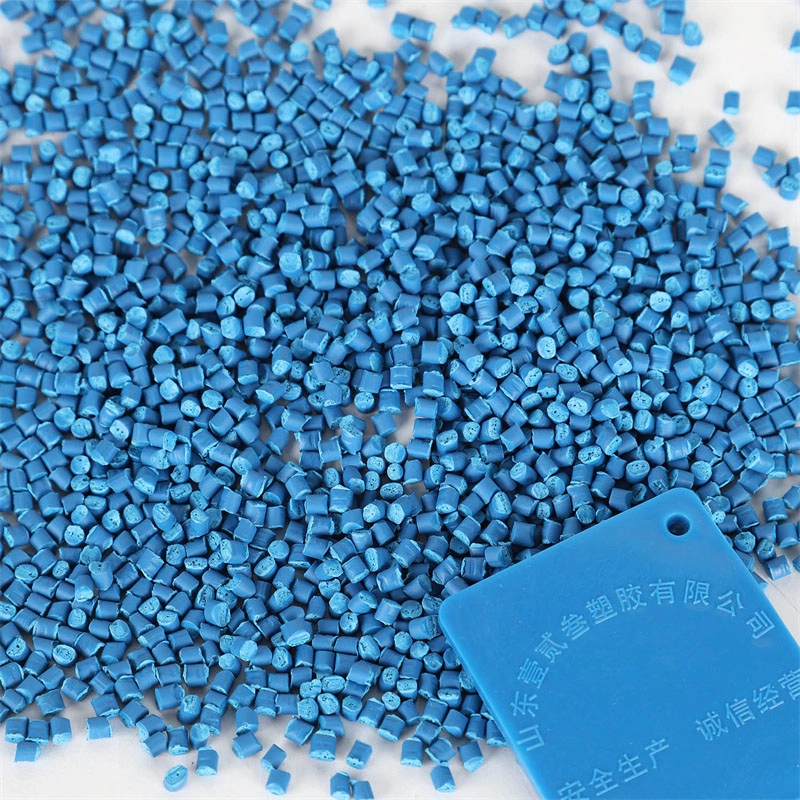

China Blue Color Masterbatch

1. High-Performance: Developing blue plastic masterbatches with improved dispersibility, stability, and weather resistance.

2. Environmental Sustainability: Adopting eco-friendly materials and technologies to reduce environmental impact.

3. Personalization: Catering to market demands by developing blue plastic masterbatches with diverse colors and properties to meet individual customer needs.

4. Intelligence Integration: Incorporating smart technologies to create blue plastic masterbatches with special functions, like temperature- or light-sensitive color changes.

Product Description

Blue plastic masterbatch is a widely used colorant in the plastic processing industry, formulated by uniformly dispersing blue pigment within a carrier resin. Here's a concise description of blue plastic masterbatch:

1. Definition: Blue plastic masterbatch is a material specifically designed for coloring plastic products, imparting a uniform blue hue when added to plastic base materials.

Characteristics:

2. Uniform Coloration: Ensures that plastic products exhibit a consistent blue color during processing, without color differences or speckles.

3. High Dispersibility: Enables the pigment to distribute evenly within the plastic base, enhancing the coloring effect.

4. Stability: Possesses good weather resistance and migration resistance, maintaining the color's stability over prolonged usage.

5. Environmental Friendliness: As environmental awareness grows, more blue plastic masterbatches are produced using eco-friendly materials, aligning with green production standards.

| Content | 10%-50% |

| Carrier | PE/PP/EVA/PVC |

| Application | PP/PE/ABS/PVC |

| MFI(g/10min) | 0.1-80 (Can be customized) |

| Melting Point(℃) | 130-170 |

| Density(g/m3) | 1.2-1.8 |

| Moisture Content(%) | ≤0.15 |

| Grain Diameter(mm) | 1.8-3.8 |

| Package | 25kgs plastic compound bag, 5kg vacuum package |

| Add Ratio | Recommend to add 2%-5% |

Application

Blue plastic masterbatch finds extensive applications in the production of various plastic products, including but not limited to:

1. Packaging: Such as blue plastic bags, blue plastic bottles, for food, pharmaceutical, and cosmetic product packaging.

2. Construction: Used in the manufacture of blue plastic pipes, insulation materials, enhancing buildings' aesthetics and durability.

3. Automotive: For coloring interior trims and components, meeting the color requirements of the automotive industry.

4. Electronics and Appliances: In the production of blue casings, buttons, and other electronic components.