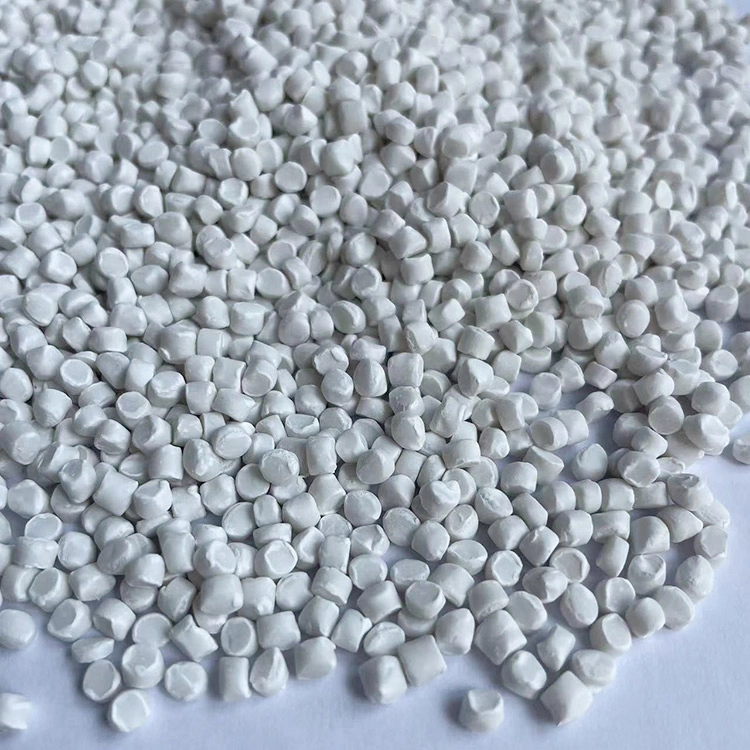

Pipe Grade CaCO3 Filler Masterbatch

1. The cost is greatly reduced. According to the calculation of 10% - 20% addition ratio, the cost of products is reduced by 1000-2000 yuan per ton compared with the original cost.

2. Strengthen the rigidity of products and increase the weight of products.

3. Good dispersibility: it has good solubility with polypropylene and polyethylene, so even if a large amount of filling is added, a good appearance with good surface finish can be obtained.

4.High Whiteness: This product is pure white granular material, which can be flexibly prepared to produce various color products.

Product Description

CaCO3 Filler Masterbatch is a kind of white plastic granule with PE/PP as carrier. CaCO3 is the main component. The mesh of CaCO3 is determined by the user's use effect, generally 500 mesh to 1250 mesh. Such masterbatch can be widely used in PE, PP, ABS and other plastic products. The adding ratio of CaCO3 masterbatch is 5%-40%.

CaCO3 filler masterbatch | |

Index | Data |

Carrier | PE/PP |

Content of Calcium Carbonate | 75%-85% |

MFI 5KG/200℃ | 5-40g /10min |

Density | 1.8-2.2g/㎝³ |

Dissolution Temperature | 140℃-200℃ |

Phase Fusibility | PE/PP/EVA |

Application

The price of CaCO3 filler masterbatch is generally cheaper than NaSO4 and BaSO4 filler masterbatch. CaCO3 filler masterbatch is generally applicable to plastic products which do not require high whiteness and transparency such as pipes, drain pipes, injection molding products, blowing molding products, sheets and the like. The general amount added can vary from 5 to 40% depending on the product requirements.