High-quality Custom Color Concentrates

1. Customization: Tailored to meet specific color requirements, ensuring unique and precise shades for diverse applications.

2. Cost-Effective: Reduces the need for large volumes of pigment, lowering overall production costs.

3. High Performance: Offers excellent dispersion and consistency, ensuring high-quality results.

4. Versatility: Suitable for a wide range of industries, including plastics, coatings, and textiles.

5. Environmental Benefits: Can reduce waste and improve sustainability by using concentrated formulas.

6. Time Efficiency: Quick mixing and easy integration into production processes.

Product Description

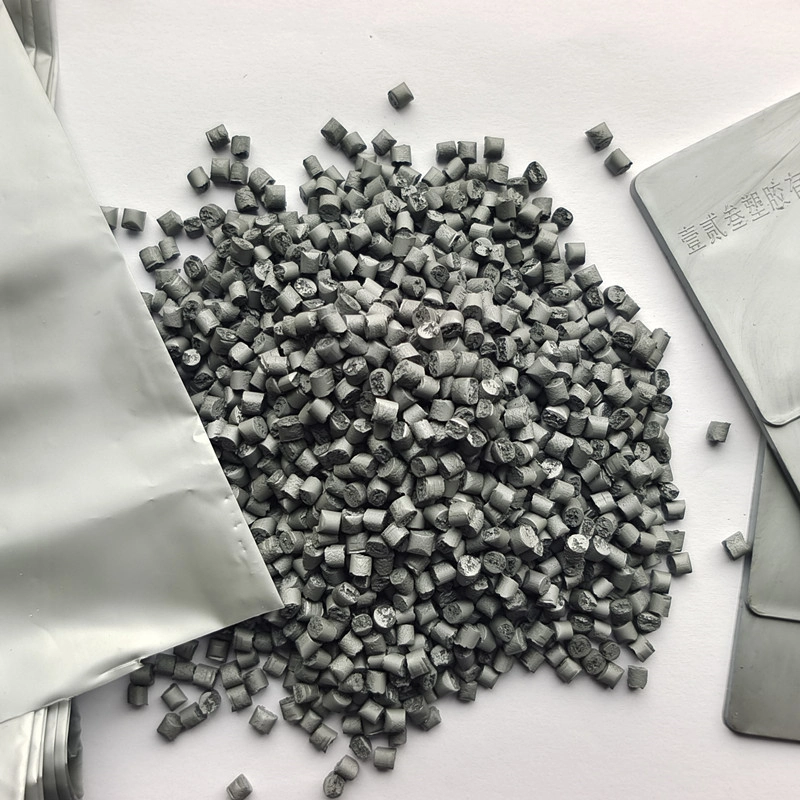

High-quality Custom Color Concentrates is a raw material used to create color for plastic products, thereby satisfying aesthetic demands. The production process starts from mixing high-quality pigments, base resin and some special additives, through the granulation process to produce the final product - Color Concentrates .

Product Parameters

| Index | Data |

| Carrier | HDPE/LDPE/PP/PLA/PVC/PET/EVA/PA |

| Color | Yellow/Red/Grey/Green/Brown.... |

| Light and weather resistant | 6-8Grade |

| MFI 21.6KG/200℃ | 1-50g/10min |

| Recommended Diagnose | 2%-4% |

Product Application

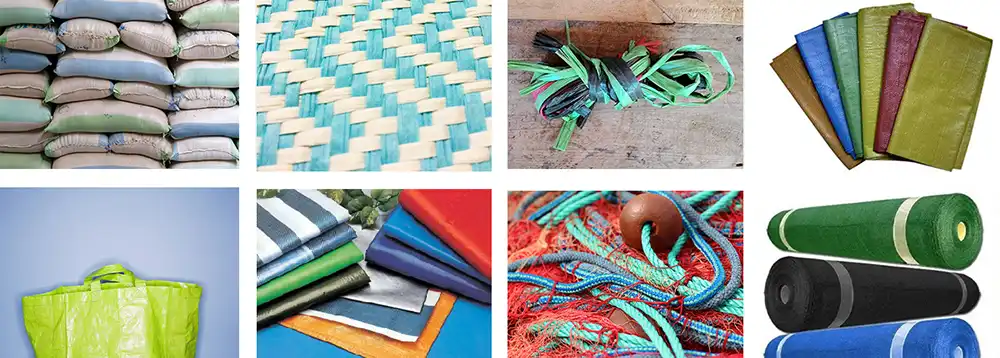

High-quality Custom Color Concentrates are widely used in various industries for adding color to plastic products. Common applications include packaging materials, automotive parts, household items, and electronics. They are also used in textiles, fibers, and films, offering consistent color quality and high stability. The versatility of color masterbatches makes them ideal for extrusion, injection molding, blow molding, and other plastic processing methods. Additionally, they help enhance product aesthetics, improve market appeal, and maintain uniformity across large-scale production runs. Their ease of use and customizable nature make them essential in manufacturing processes.