Rotational Molding

Our masterbatch materials support all processing technologies, including rotational molding.

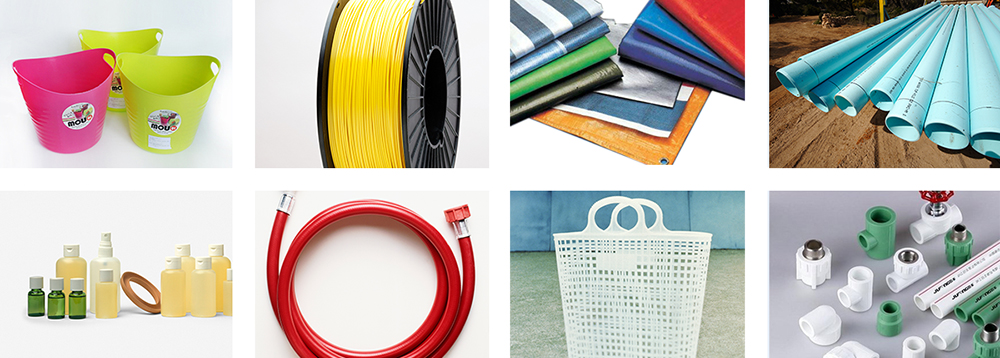

There are many types of rotational molded plastic products. Commonly seen ones include the following categories:

1. **Container products**:

- **Storage tanks**: Used for storing various liquid or solid materials, such as chemical raw materials, oils, foods, water, etc. For example, chemical storage tanks commonly used in chemical enterprises and raw material storage tanks in the food processing industry have good corrosion resistance and sealing performance.

- **Water tanks**: Including domestic water tanks, fire water tanks, industrial water tanks, etc. Rotational molded water tanks can be customized in size and shape according to different needs, and are easy to install and not prone to rust and corrosion.

- **Trash cans**: Various trash cans used in streets, communities, parks, shopping malls and other places. Rotational molded trash cans are bright in color, wear-resistant, and anti-aging, and can adapt to different environmental conditions. - **Turnover boxes**: Widely used in logistics, warehousing, transportation and other industries for the storage, handling and turnover of goods. Rotational molded turnover boxes have high strength, light weight, and are easy to stack.

2. **Automotive parts products**:

- **Fuel tanks**: Rotational molded fuel tanks are lightweight, not prone to rust, not easy to leak, and have high safety. They can be custom-designed according to the space requirements of different vehicle models and are widely used in automobiles, motorcycles, construction machinery and other fields.

- **Mudguards**: Installed above vehicle tires to prevent mud, rainwater and other splashes from reaching the vehicle body and protect the vehicle body from pollution and corrosion. Rotational molded mudguards have good toughness and impact resistance and can adapt to various complex road conditions.

- **Roofs**: The roofs of some automobiles can be manufactured by rotational molding. They have good heat insulation and sound insulation performance, and can be designed into different shapes and colors to meet the appearance design requirements of automobiles.

- **Air conditioning pipes**: Such as air conditioning elbows. The rotational molding process can manufacture pipe fittings with complex shapes to meet the installation and use requirements of automotive air conditioning systems.

3. **Sports equipment and amusement facility products**:

- **Fitness equipment**: Such as dumbbells, barbell plates, fitness bike seats, etc. Rotational molded fitness equipment has a beautiful appearance, a comfortable feel, and good wear resistance and anti-aging performance, and can meet people's long-term use needs.

- **Amusement facilities**: Components of large amusement facilities such as children's slides, carousels, seesaws, and floating rings, floating boards, and water slides in water parks. Rotational molded amusement facilities are safe and reliable, brightly colored, and can bring joy and fun to children.

- **Sports equipment accessories**: Such as bicycle saddles, water polo balls, floating balls, surfboards, etc. These rotational molded products have good elasticity and buoyancy and can improve the performance and safety of sports equipment.

4. **Furniture and outdoor products**:

- **Tables and chairs**: Rotational molded tables and chairs are lightweight, easy to move, and not easy to damage. They are suitable for use in outdoor, courtyard, garden and other places. And tables and chairs of various shapes and colors can be manufactured according to different design styles and needs.

- **Flower pots**: Rotational molded flower pots have diverse shapes and can simulate the texture and appearance of materials such as ceramics and stone. At the same time, they are lightweight, durable, and not easy to break. They are suitable for flower planting indoors and outdoors.

- **Outdoor products**: Accessories such as tent pegs and rope buckles for camping tents, and the housings and lampshades of outdoor lamps can all be manufactured by rotational molding. They have good waterproof, dustproof, and UV-resistant properties.

5. **Industrial equipment and accessories products**:

- **Machine housings**: Used to protect the internal parts of machinery and equipment and prevent dust, moisture, oil stains, etc. from entering the machine and affecting the normal operation of the equipment. Rotational molded machine housings have good sealing performance and impact resistance and can adapt to various harsh working environments.

- **Protective covers**: Installed on dangerous parts of machinery and equipment, such as rotating parts and transmission parts, to play a role in safety protection. Rotational molded protective covers have high transparency and high strength and can effectively protect the safety of operators.

- **Washing tanks and reaction tanks**: In the production processes of chemical, pharmaceutical, food and other industries, washing tanks and reaction tanks are needed for operations such as material cleaning and reaction. Rotational molded washing tanks and reaction tanks have good corrosion resistance and high temperature resistance and can meet the requirements of different processes.

6. **Other products**:

- **Mannequins**: Mannequins used in clothing displays and window displays. Rotational molded mannequins can be made into realistic human body shapes and postures and have good stability and durability.

- **Roadblocks**: Roadblocks used in traffic control and road construction occasions. Rotational molded roadblocks are eye-catching in color and moderate in weight, and are easy to move and set up.

- **Floats**: Such as the floating parts of buoys, floating bridges, floating docks, etc. Rotational molded floats have good buoyancy and stability and can be used on water for a long time.