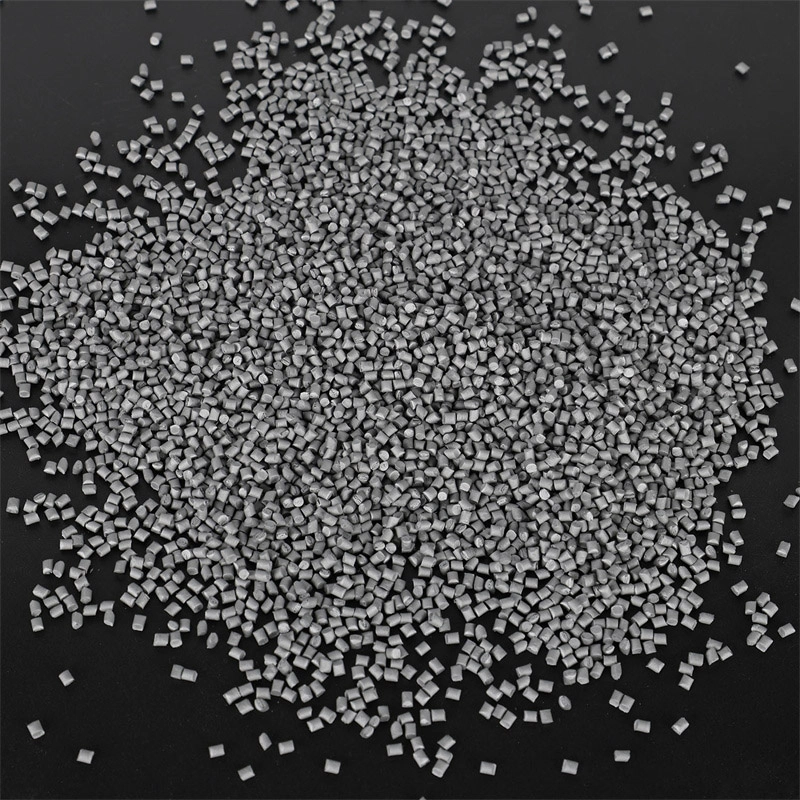

Cheap Gray Masterbatch

1. Uniform and Stable Color: Gray plastic masterbatch ensures consistent coloration in plastic products during processing, maintaining color stability over extended periods without fading.

2. Excellent Dispersion and Flowability: It evenly disperses within the plastic base material, preventing color inconsistencies and speckles, enhancing production efficiency, reducing energy consumption, and minimizing waste.

3. Superior Physical Properties: Depending on the specific formulation and manufacturing process, gray plastic masterbatch may exhibit high temperature resistance, weather resistance, corrosion resistance, and other exceptional properties to meet specific industry demands for plastic products.

4. Environmental Friendliness: Amidst growing environmental awareness, many gray plastic masterbatch manufacturers adopt eco-friendly raw materials and production processes to minimize environmental impact and promote sustainability.

Product Description

Gray plastic masterbatch, as an essential raw material in the plastic processing industry, boasts numerous notable characteristics and application values. With advancing technologies and stricter environmental regulations, the gray plastic masterbatch industry is evolving towards higher performance and greater environmental friendliness. Future holds the promise of more innovative gray plastic masterbatch products, presenting both opportunities and challenges for the plastic processing industry. Additionally, enhancing the recycling of waste plastics and promoting biodegradable plastics are crucial pathways to address current environmental concerns.

| Content | 10%-50% |

| Carrier | PP/PE/EVA/PVC |

| Application | PP/PE/ABS/PVC |

| MFI(g/10min) | 0.1-80 (Can be customized) |

| Melting Point(℃) | 130-170 |

| Density(g/m3) | 1.2-1.8 |

| Moisture Content(%) | ≤0.15 |

| Grain Diameter(mm) | 1.8-3.8 |

| Package | 25kgs plastic compound bag, 5kg vacuum package |

| Add Ratio | Recommend to add 2%-5% |

Application

Gray plastic masterbatch is widely used in various plastic processing techniques such as injection molding, blow molding, and extrusion, suitable for producing plastic containers, buckets, pipes, pallets, and more. These products find applications across packaging, construction, transportation, agriculture, and other sectors, significantly impacting daily life and industrial production.